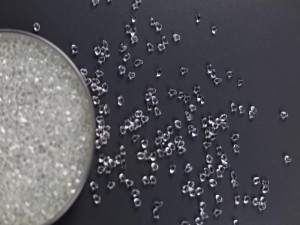

Letoto la E*U la Ponaletso e Ntle le ho hanyetsa UV Resistance TPU

Likaroloana

Ponahalo e Ntle le ho hanyetsa UV, Ts'ebetso e Ntle, Khahlano e Ntle ea ho falla, Mobala o motle, o Loketse Electroplating, Printing, Coating le theknoloji e 'ngoe ea ts'ebetso ea bobeli.

Kopo

Sekoaelo sa Phone&Pad, Sehlopha sa ho shebella, Lieta, joalo-joalo

| Thepa | Standard | Yuniti | E85U | E90U | E190LU | E95U |

| Botenya | ASTM D792 | g/cm3 | 1. 18 | 1. 18 | 1. 19 | 1. 18 |

| Ho thatafala | ASTM D2240 | Shore A/D | 88/- | 92/- | 92/- | 95/- |

| Matla a tšepe | ASTM D412 | MPa | 38 | 40 | 40 | 42 |

| 100% Modules | ASTM D412 | MPa | 8 | 10 | 10 | 12 |

| 300% Modules | ASTM D412 | MPa | 18 | 24 | 20 | 28 |

| Elongation at Break | ASTM D412 | % | 500 | 450 | 500 | 400 |

| Matla a Kgapha | ASTM D624 | kN/m | 110 | 125 | 140 | 145 |

| Khanyetso e mosehla | ASTM D1148 | Kereiti | 4 | 4 | 3.5 | 4 |

| Tg | DSC | ℃ | -22 | -20 | -25 | -18 |

ELA HLOKO: Lintlha tse ka holimo li bonts'itsoe e le litekanyetso tse tloaelehileng 'me ha lia lokela ho sebelisoa e le litlhaloso.

Tataiso ea Ts'ebetso

Bakeng sa liphetho tse ntle, ho omisoa ha sehlahisoa pele ho lihora tse 3-4 ka mocheso o fanoeng ho TDS.

Lihlahisoa li ka sebelisoa bakeng sa ho etsa ente kapa extrusion, 'me ka kopo sheba lintlha tse ling ho TDS.

| Tataiso ea Ts'ebetso bakeng sa Mold ea Ente | Tataiso ea ho sebetsa bakeng sa Extrusion | |||

| Ntho | Paramethara | Ntho | Paramethara | |

| Nozzle(℃) | E fanoe ho TDS | Lefu(℃) | E fanoe ho TDS | |

| Metering Zone(℃) | Adapter(℃) | |||

| Compression Zone(℃) | Metering Zone (℃) | |||

| Feeding Zone(℃) | Compression Zone (℃) | |||

| Khatello ea Ente(bar) | Feeding Zone (℃) | |||

Tlhahlobo

Lihlahisoa tsohle li hlahlojoa hantle nakong ea tlhahiso le ka mor'a tlhahiso. Setifikeiti sa Tlhahlobo (COA) se ka fanoa hammoho le lihlahisoa.

P: O ka fana ka mehlala?

A: Re ka fana ka mehlala. Ka kopo ikopanye le rona bakeng sa mehlala

P: Ke boema-kepe bofe boo u ka tsamaisang thepa?

A: Qingdao kapa Shanghai.