H Series High Bonding & Peeling Strength Hotmelt Adhesive TPU

Features

Excellent Elasticity, High Bonding&Peeling Strength, Outstanding Recovery Property.

Application

Hotmelt Film and Tape, Fabric Coating, Toe Puffs&Counters, etc.

| Properties | Standard | Unit | H190E | H220E | H290 | H290H | H295 | H370 | H570 | H680 | H680U | H680A | H690 | H70A |

| Density | ASTM D792 | g/cm3 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 |

| Hardness | ASTM D2240 | A | 97 | 95 | 97 | 97 | 95 | 70 | 75 | 80 | 80 | 80 | 90 | 75 |

| Tensile Strength | ASTM D412 | MPa | 25 | 35 | 20 | 25 | 25 | 15 | 15 | 25 | 25 | 25 | 30 | 20 |

| Elongation at Break | ASTM D412 | % | 800 | 650 | 700 | 700 | 700 | 800 | 800 | 600 | 600 | 750 | 450 | 800 |

| Tfb | - | ℃ | 70 | 85 | 60 | 60 | 60 | 97 | 95 | 110 | 110 | 110 | 135 | 95 |

| Tack-Free Time | - | min | 5 | 13 | 4 | 4 | 3 | 10 | 8 | 6 | 6 | 1 | 4 | 3 |

NOTE: The above values are shown as typical values and should not be used as specifications.

Processing Guide

For optimum results, previous drying of the product during 3-4 hours at given temperature in the TDS.

The products can be used for injection molding or extrusion, and please check more details in the TDS.

| Processing Guide for Injection Molding | Processing Guide for Extrusion | |||

| Item | Parameter | Item | Parameter | |

| Nozzle(℃) |

Given in the TDS |

Die(℃) | Given in the TDS | |

| Metering Zone(℃) | Adapter(℃) | |||

| Compression Zone(℃) | Metering Zone (℃) | |||

| Feeding Zone(℃) | Compression Zone (℃) | |||

| Injection Pressure(bar) | Feeding Zone (℃) | |||

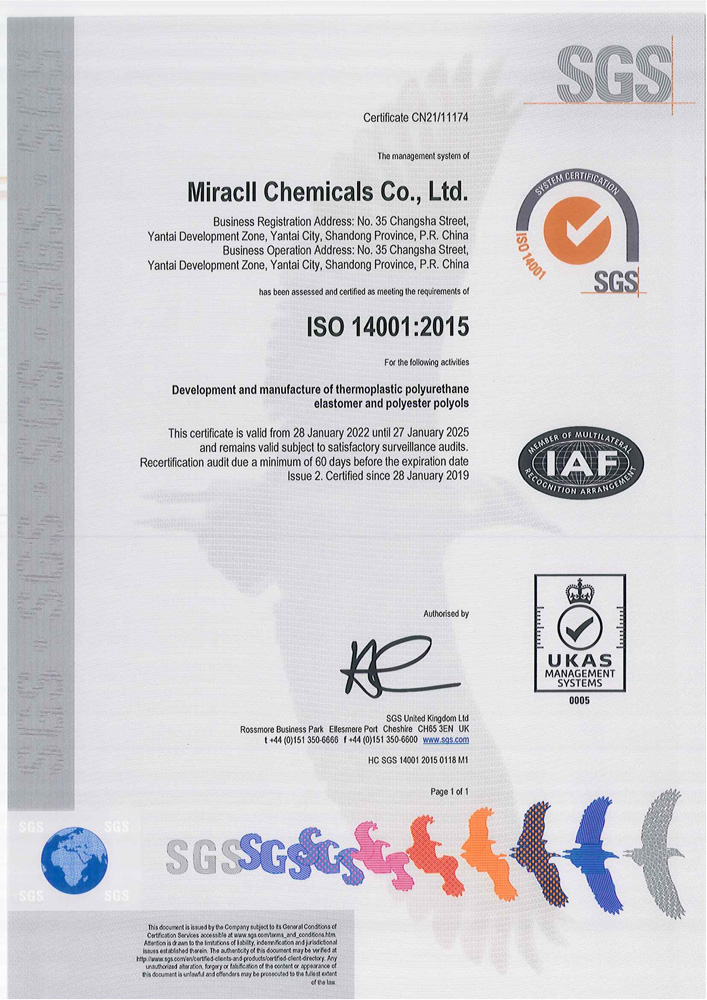

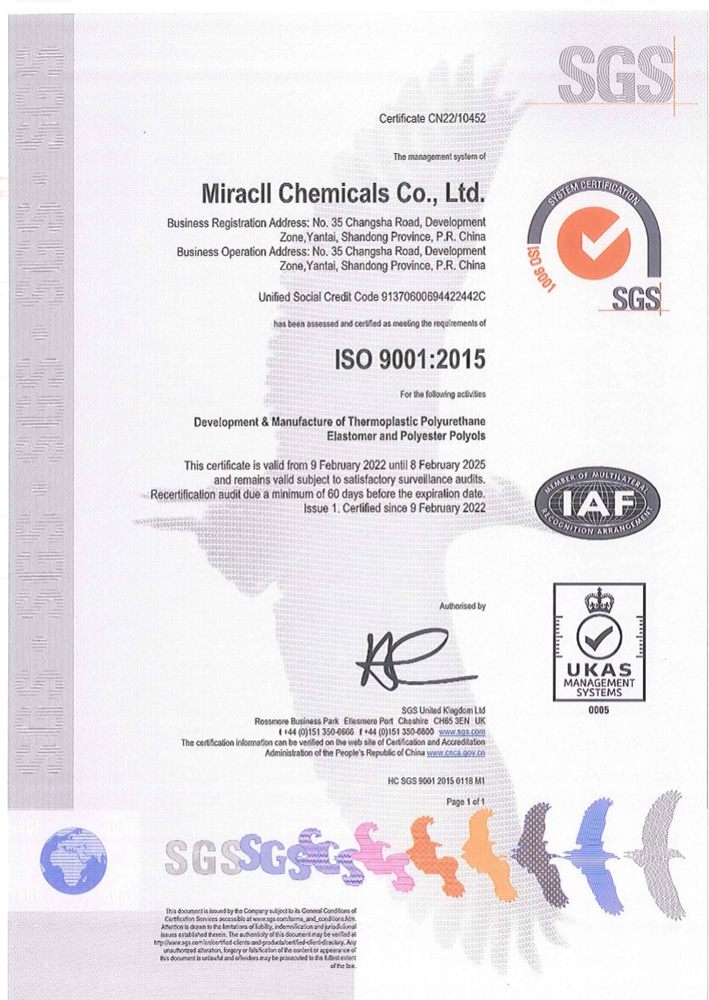

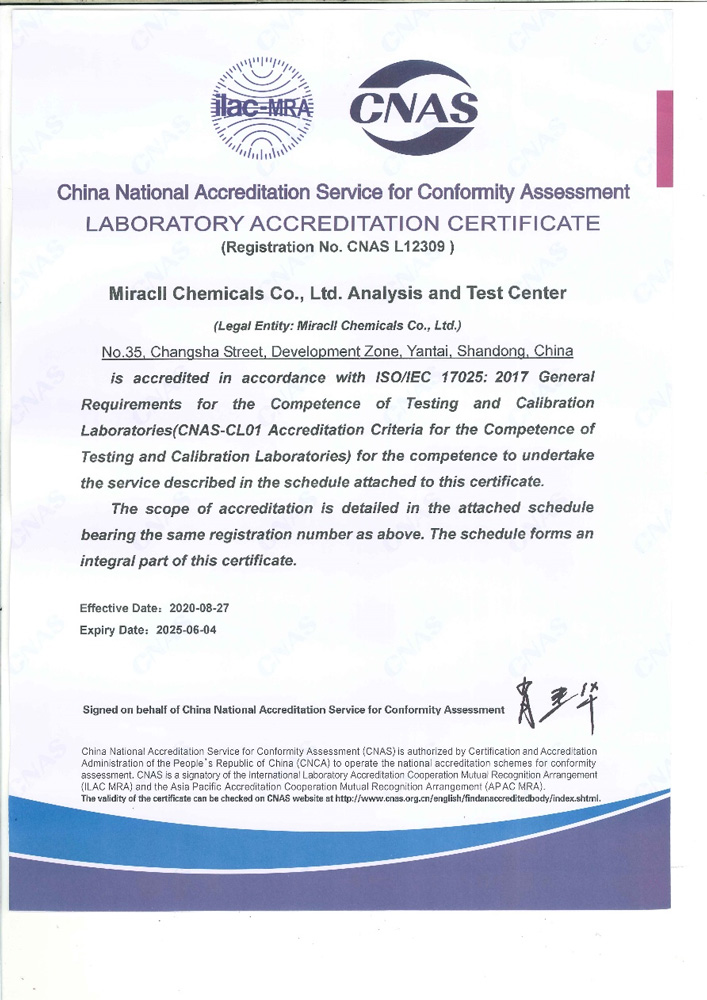

Certifications

We have full certifications, such as ISO 9001, ISO 14001, ISO 45001, IATF 16949, CNAS National Laboratory

Q: Can you provide samples?

A: We can provide samples. Please contact us for the samples

Q: Which port can you deliver the cargo?

A: Qingdao or Shanghai.

Q: How about the lead time?

A: It’s usually 30 days. For some normal grades, we can make delivery immediately.

Q: What about the payment?

A: It should be payment in advance.