Factory Outlets 55A TPU - A Series Non-Yellowing Aliphatic TPU – Miracll

Factory Outlets 55A TPU - A Series Non-Yellowing Aliphatic TPU – Miracll Detail:

Features

Non-Yellowing, Excellent Transparency, Migration Resistance, Less Fisheye

Application

PPF for Automotive, Automotive Interior Decoration, Watchband, Hose&Tube, Wire&Cable, Optical Glasses, Film, etc.

| Properties |

Standard |

Unit |

A285 |

A290 |

A295 |

| Density |

ASTM D792 |

g/cm3 |

1.13 |

1.16 |

1.18 |

| Hardness |

ASTM D2240 |

Shore A/D |

85/- |

90/- |

95/- |

| Tensile Strength |

ASTM D412 |

MPa |

25 |

25 |

30 |

| 100%Modulus |

ASTM D412 |

MPa |

5 |

6 |

13 |

| 300%Modulus |

ASTM D412 |

MPa |

13 |

15 |

28 |

| Elongation at Break |

ASTM D412 |

% |

400 |

350 |

320 |

| Tear Strength |

ASTM D624 |

kN/m |

75 |

85 |

145 |

| Tg |

DSC |

℃ |

-40 |

-37 |

-32 |

NOTE: The above values are shown as typical values and should not be used as specifications.

Processing Guide

For optimum results, previous drying of the product during 3-4 hours at given temperature in the TDS.

The products can be used for injection molding or extrusion, and please check more details in the TDS.

| Processing Guide for Injection Molding | Processing Guide for Extrusion | |||

| Item | Parameter | Item | Parameter | |

| Nozzle(℃) |

Given in the TDS |

Die(℃) | Given in the TDS | |

| Metering Zone(℃) | Adapter(℃) | |||

| Compression Zone(℃) | Metering Zone (℃) | |||

| Feeding Zone(℃) | Compression Zone (℃) | |||

| Injection Pressure(bar) | Feeding Zone (℃) | |||

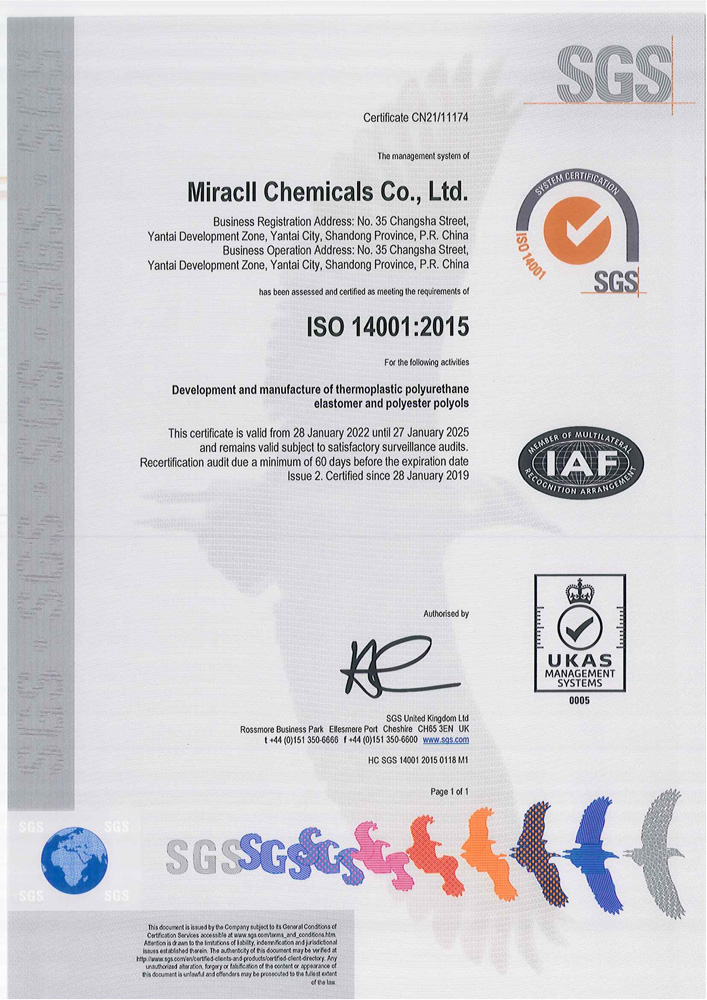

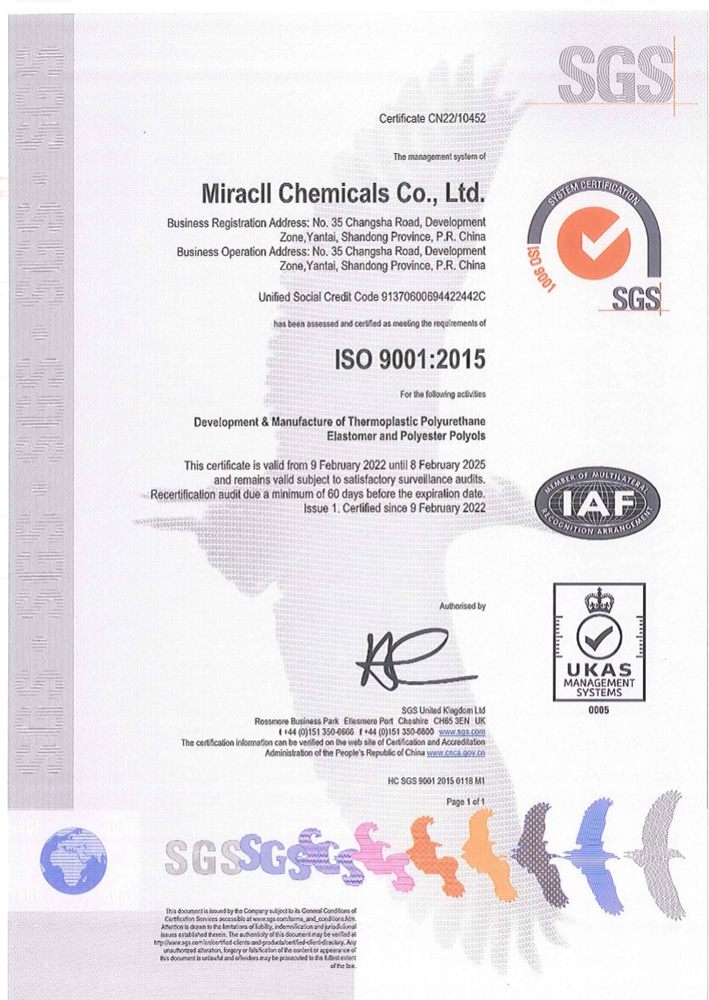

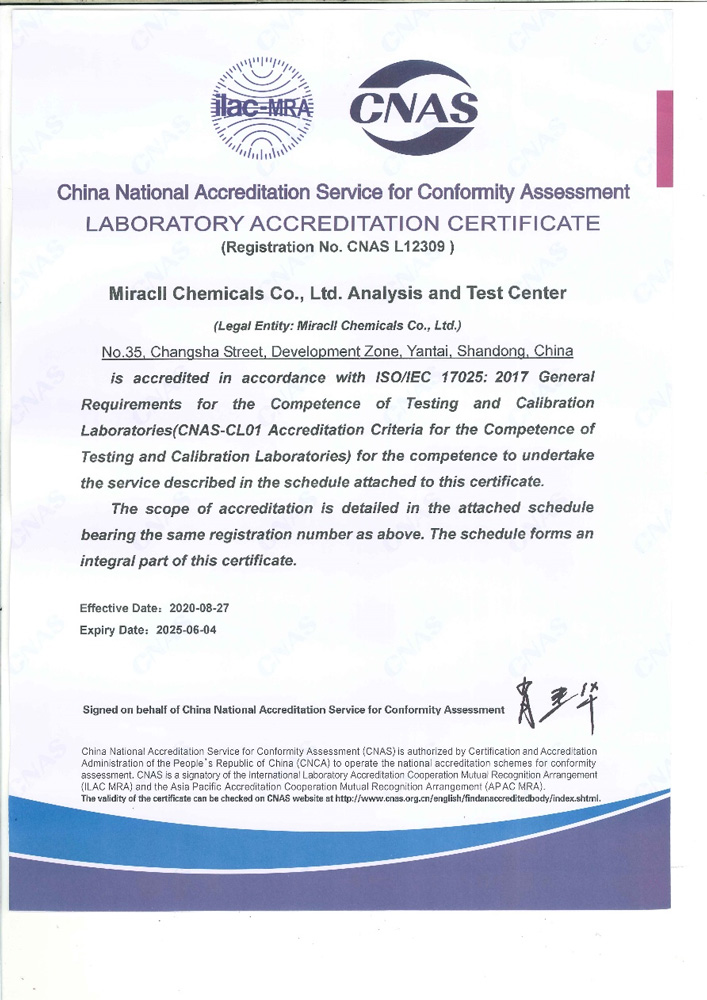

Certifications

We have full certifications, such as ISO 9001, ISO 14001, ISO 45001, IATF 16949, CNAS National Laboratory

Product detail pictures:

Related Product Guide:

We stick with the theory of "quality first, company first, steady improvement and innovation to satisfy the customers" for the management and "zero defect, zero complaints" as the quality objective. To perfect our provider, we deliver the items together with the fantastic good quality at the reasonable value for Factory Outlets 55A TPU - A Series Non-Yellowing Aliphatic TPU – Miracll , The product will supply to all over the world, such as: Zambia, Cyprus, Florida, Our well-equipped facilities and excellent quality control throughout all stages of production enable us to guarantee total customer satisfaction. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact me. We are looking forward to forming successful business relationship with new clients around the world.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!